Santa’s New Toy-making and Delivery Operations Center (TDOC)

For Santa Claus and his elfin crew, the season of good cheer is anything but. Every year, Santa deals with the logistical nightmare of manufacturing and delivering toys and treats to good children all over the world in an extremely short timeframe. The whirlwind of activity leading up to Christmas Eve has typically been a time of intense stress for Jolly Ol’ Saint Nick. That is, until now…

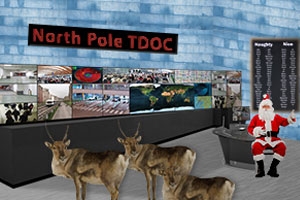

This year’s toy manufacturing and delivery is on track to become the smoothest operation to date, thanks to Santa’s new state-of-the-art Toy-making and Delivery Operations Center (TDOC), fully equipped with RGB Spectrum’s cutting-edge display processing and control management technologies. Santa is thrilled with his new system. “The system is sophisticated enough to handle the multiple competing demands of this large-scale enterprise,” he observed, “but is intuitive enough that, in a pinch, even a reindeer can operate it!”

“We are proud to be able to support Santa in his toy-making ventures” remarked Bob Marcus, President and CEO of RGB Spectrum. “Santa works tirelessly for months on end to make sure that Christmas is a joyful occasion for girls and boys all over the world. This year, we wanted to give Santa a gift. The sleek new Operations Center will lighten Santa’s load and make the holidays a more joyful (and less stressful) time for Santa Claus and all of his helpers.”

Santa’s toy factory operates on a massive scale; even the largest toy-making enterprises outside of the North Pole pale in comparison. Employing over 50,000 elves and operating on a 24/7 basis, Santa’s 500 factories produce nearly 2 billion toys each year.

Previously, the only way that Santa Claus could oversee the manufacturing was to send one of his designated head elves to visit each facility in person. Lacking sufficient elf-power, quality control was hit or miss because it was impossible for Santa to monitor the entire system as required. When there was a problem at a factory, all toy production would cease until the appropriate personnel could travel to the site, diagnose and resolve the issue, and give approval to resume operations. This would typically lead to serious delays and backlogs, further compounding the logistical nightmare of the Christmas enterprise.

The centerpiece of Santa’s new Operations Center is a massive 3x10 video wall controlled by an OmniWall™ Display Processor, which enables the display of multiple video and graphic input sources on any monitor in the system. The processor works with a MultiPoint® Control Room Management System (MCMS) to streamline operations monitoring and control at the North Pole.

The new OmniWall/MCMS system consolidates control of various disparate manufacturing and delivery subsystems to make it easier for Santa to oversee the progress of his toy-making operations. These include access control and video management systems (VMS) as well as SCADA systems that monitor toy factory equipment. Twenty control stations allow senior elves to access and control any of the subsystems and choose which sources to display on the video wall.

Video feeds from thousands of cameras are streamed into a VMS server, where they can be accessed through the MCMS. When there is an issue at any facility, an elf can immediately call up video feed of the situation to diagnose and resolve the problem. The control arbitration feature of the system enables each elf to request control of specific system resources. Santa Claus himself can take immediate control of the entire system to deal with an emergency situation.

The MCMS also provides operators with the ability to control equipment remotely. All toy-making machines can be operated through the MCMS GUI, and this allows elves at the consolidated Operations Center to be able to quickly resolve site specific manufacturing issues from their individual workstations.

By streamlining operations and monitoring processes, the OmniWall/MCMS system has boosted production capacity by a staggering 1225%. To date, the elves have manufactured 99% of the toys required, and Santa is eagerly anticipating the novelty of having a restful day or two to spend with Mrs. Claus before commencing his toy delivery marathon.

When the big night comes around, Santa will no longer have to rely exclusively on Rudolph’s nose for navigation. Though the reindeer will still guide Santa’s sleigh, the elves at the Operations Center will also continually monitor satellite feeds, commercial weather stations, and NASA communications to optimize Santa’s journey and help him avoid inclement weather conditions and low flying aircraft.

So far, Santa is full of praise for the efficient operation and 24/7 reliability of the system. He looks forward to testing the remaining features of the system once toy delivery commences. “By providing us with such innovative equipment, RGB Spectrum has saved Christmas!” remarked Santa. “Year after year of Christmas stress was taking its toll on my health and well-being. With the ballooning population of children worldwide, I was starting to believe that the elves and I would not be able to keep it up much longer. But RGB Spectrum’s OmniWall/MCMS system provides me with the support I need combined with outstanding image quality and feature-packed functionality. With RGB Spectrum’s equipment on our side, I have no doubt that my toy-making enterprise will survive and thrive for many years to come.”

RGB Spectrum is a leading designer and manufacturer of mission-critical, real-time audio-visual solutions for a civilian, government, and military client base. The company offers integrated hardware, software, and control systems to satisfy the most demanding requirements. Since 1987, RGB Spectrum has been dedicated to helping its customers achieve Better Decisions. Faster.™